銷售熱(rè)線(xiàn):15060899237

電話(huà):0595-86799999

傳真(zhēn):0595-86783555

電子郵件:xdm.neo@gmail.com

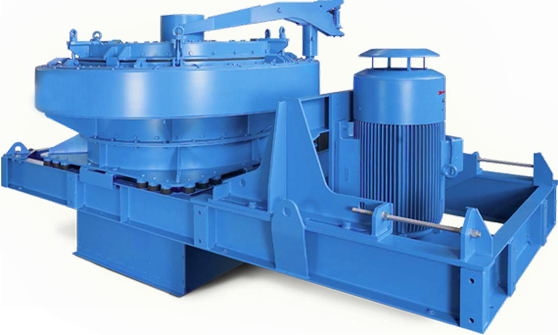

mr 轉子離心式制(zhì)砂機 mr rotor centrifugal crusher

一(yī)、 産品簡(jiǎn)介 product description

mr 轉(zhuǎn)子離心式(shì)破碎機是一款(kuǎn)配有(yǒu)立(lì)軸的高(gāo)性能破(pò)碎機 , 它适用(yòng)于所有類(lèi)型的礦物破碎和整形 : 從軟質(zhì)物料到硬(yìng)質物(wù)料 , 無論(lùn)是(shì)低磨(mó)損還是極高磨(mó)損的(de)材質。物料(liào)中的每個顆粒(lì)在雙腔式轉子(zǐ)中高速旋轉 , 然(rán)後甩(shuǎi)向固定的(de)反擊闆 , 反(fǎn)擊闆可由(yóu)環形(xíng)襯闆(pǎn)或由砂(shā)床組(zǔ)成(chéng) , 通過轉子和殼(ké)體的(de)寬大尺寸(cùn)設計(jì)在很大程(chéng)度 , 避免了堵塞(sāi)。而且(qiě)該款制砂(shā)機大(dà)的優(yōu)勢是(shì)整個(gè)轉子無焊接部(bù)分(fèn) ,; 所有耐(nài)磨防護(hù)爲單個(gè)可更換的易提件 ., 與(yǔ)多腔式設(shè)計相比 , mr 轉(zhuǎn)子離(lí)心式(shì)破碎(suì)機采用的雙腔(qiāng)式轉(zhuǎn)子中(zhōng)輸送的(de)空(kōng)氣更少 , 降低了(le)能耗 , 所節(jiē)省的(de)能量可用(yòng)于提(tí)高 , 産能 , 同時也(yě)降低了除塵裝(zhuāng)置的功率 , 雙腔(qiāng)式轉(zhuǎn)子(zǐ)具有開放式結構設計 , 從(cóng)而(ér)允(yǔn)許(xǔ)出料口的(de)可用尺寸達到(dào)最大 ( 每側(cè) 89" ), 這樣顯(xiǎn)著地降低了物料堵塞的風(fēng)險 , 在 mr 雙腔(qiāng)式轉子中(zhōng)沿(yán)破碎腔會形成一(yī)個物料(liào)層 , 可作(zuò)爲自(zì)身磨損保(bǎo)護。與(yǔ)傳統(tǒng)型轉(zhuǎn)子相(xiàng)比(bǐ) , 所需磨(mó)損件比(bǐ)例(lì)降至(zhì)最小(xiǎo) .

mr rotor centrifugal crusher is a high performance of vertical crusher. it applies to all types of mineral crushing and shaping: material from soft to hard material. the material of both low wear and high wear. each particle in the material in the high speed rotating rotor double cavity, slammed to counterattack plate fixed. counterattack plate can be made of annular plate or consists of a sand bed. through the large size of the rotor and shell design to a great extent, to avoid the jams. and the big advantage is the whole rotor system sand machine welding parts, all wear protection for a single replaceable parts.compared with multiple cavity design, mr rotor centrifugal crusher with double cavity of the rotor in the conveying air less and to reduce the energy consumption and save energy can be used to increase production capacity, but also reduce the power of the dust removal device.double rotor cavity with open architecture design, allowing the discharging mouth of the maximum available size (89) on each side. this significantly reduce the risk of material jam.in mr double rotor cavity along the crushing cavity can form a layer of material, can be used as its own wear protection. compared with the traditional rotor. the wear ratio fell to a minimum.

二、 産(chǎn)品特(tè)點 product features

·高(gāo)品質的最(zuì)終産品生産優(yōu)質立方體(tǐ)型(xíng)産(chǎn)品 , 利(lì)用離心力(lì)使進料的每個顆粒(lì)在(zài)轉子中(zhōng)獲(huò)得極大的加(jiā)速度(dù) , 物料抛出(chū)後與破碎(suì)闆碰(pèng)撞。通(tōng)過(guò)強大的(de)沖擊(jī)力可使最(zuì)終産品獲得極(jí)其理想的(de)立方體形狀。

·質量穩(wěn)定的最終産品(pǐn)即使設備(bèi)在運(yùn)行中不(bú)斷地産(chǎn)生磨(mó)損(sǔn) , 也絲(sī)毫(háo)不會影響(xiǎng)物料(liào)的破(pò)碎效果。其(qí)系統特性能夠避(bì)免(miǎn)物料(liào)破碎(suì)時産生(shēng)随(suí)機效(xiào)應。這(zhè) 1 也(yě)是(shì) mr 轉子(zǐ)離心式(shì)破(pò)碎機(jī)不同(tóng)于(yú)其它傳(chuán)統破碎技術的特點(diǎn) .

·有針對(duì)性(xìng)的選擇性(xìng)破碎(suì)通讨(tǎo)對每(měi)個物(wù)料顆粒針對性(xìng)的沖(chòng)擊(jī)破碎 , 使(shǐ)低強(qiáng)度(dù)成分的(de)物料比(bǐ)高強度(dù)成分物(wù)料(liào)更容(róng)易被(bèi)破碎(suì)。這樣便可以有目的(de)地去(qù)除掉易被(bèi)破碎(suì)部分(fèn)的物(wù)料 , 從(cóng)而(ér)顯著提(tí)高最終産品的質量(liàng) ( 磨耗值、抗(kàng)凍性 ) 。對于由不同強(qiáng)度的(de)成分(fèn)組成的原礦及工業(yè)用礦物 . 可(kě)得到最大(dà)教量(liàng)的最(zuì)終産品 .

• high quality of the final product produce the high quality cubic shape products,use centrifugal force to make every feeding grain get the great accelerated speed the casted materials crush with crushing plate.

• the quality stable's final product even if the equipment in operation cause abrasion continually, also doesn't affect the material's crush effect. the system features can avoid the random-effects by material crushing . this is mr rotor centrifugal crusher's technology characteristics different from other traditional's.

• targeted selective crushing for each material particles through targeted shock crushing,the low intensity component materials is easier crushed then high intensity component.in this way.it can remove the easy crushing part's materials on purpose,thus,significantly improve the quality of the final product(wear value.freezing resistance).for the different intensity of components of ores and industrial minerals. can get the largest number's final product.

the annular plate structure / 環(huán)形襯闆

環形襯闆結(jié)構的典型(xíng)應用範圍(wéi)

·适用(yòng)于使用中硬、中(zhōng)等磨耗性物料生産立方型骨(gǔ)料和制砂 , 例如使用(yòng)礫石、石灰(huī)石、白(bái)雲岩、輝綠(lǜ)岩、玄武岩(yán)、安山(shān)岩、碎磚(zhuān)塊(kuài)、水泥(ní)熟料(liào)等 .

·選擇性(xìng)破碎泥礫石以(yǐ)及其他(tā)礫(lì)岩、料(liào)、表土層等。

·回(huí)收(shōu)利用(yòng)瀝青(qīng)和無(wú)鋼筋的(de)混凝土(tǔ)塊等(děng)建築垃圾 . 中等磨耗的礦(kuàng)渣、工業礦(kuàng) .

• it is suitable for medium abrasion resistance material production cubic stone and sand making, such as gravel limestone. dolomite. diabase, basalt, andesite. brick bat cement clinker etc.

• selective crushing mud gravel and other conglomerate , medium abrasion resistance material of slag and industrial mineral, topsoil, etc.

• recycling asphalt , unreinforced concrete block and construction waste. etc.

the sand bed structure/ 砂(shā)床(chuáng)結構(gòu)

砂(shā)床結構(gòu)的典型應(yīng)用範(fàn)圍

·适用于(yú)使用高(gāo)磨(mó)耗(hào)性物料(liào)生産立方(fāng)型骨(gǔ)料和制砂 , 例如(rú)使用礫石、花崗岩、斑(bān)岩、片麻岩(yán)、雜砂岩、石(shí)英石(shí)等 .

·破(pò)碎高(gāo)磨耗(hào)性物料 , 例如 : 鋁(lǚ)釩土、矽鐵、磨料(liào)、玻璃等(děng)。

·有(yǒu)選搔地破碎(suì)例如來(lái)自鋼鐵廠、焚燒爐等(děng)的礦(kuàng)渣 .

• it is suitable for high abrasion resistance material production cubic stone and sand making, such as gravel, granite and porphyry, gneiss, miscellaneous sandstone, quartz, etc .

• crushing high abrasion materials, such as aluminium vanadium and soil. ferrosilicon , abrasive , glass, etc

• selectively crushing slag from steel plant, incinerator etc.

三、 技術(shù)參數(shù) technical data

|

型号(hào)

model |

轉子(zǐ)大小(xiǎo)

rotor size |

圓周(zhōu)速度(dù)

speed |

進料粒度(dù)

feed size |

通過能(néng)力

through ability |

功(gōng)率

power |

重量(liàng)

weight |

外形尺寸(cùn)

dimension |

| d×h(mm) | (m/s) | (mm) | (t/h) | (kw) | (t) | (l×w×h)(mm) | |

| mr0913 | Φ930×135 | 60-89 | 45-56 | 30-75 | 75-160 | 7.5 | 3950×2400×2355 |

| mr0922 | Φ930×220 | 60-89 | 56-70 | 30-90 | 90-160 | 7.8 | 3950×2400×2355 |

| mr1222 | Φ1200×220 | 60-89 | 80-100 | 100-400 | 160-400 | 12.1 | 5080×2860×2675 |

| mr1233 | Φ1200×330 | 60-89 | 80-150 | 200-400 | 200-400 | 13.5 | 5080×2980×2825 |