銷(xiāo)售熱(rè)線:15060899237

電話:0595-86799999

傳(chuán)真:0595-86783555

電子郵件:xdm.neo@gmail.com

mph 高(gāo)效複(fú)合(hé)圓(yuán)錐破系列(liè) mph combined cone crusher

一、 産品簡介 product description

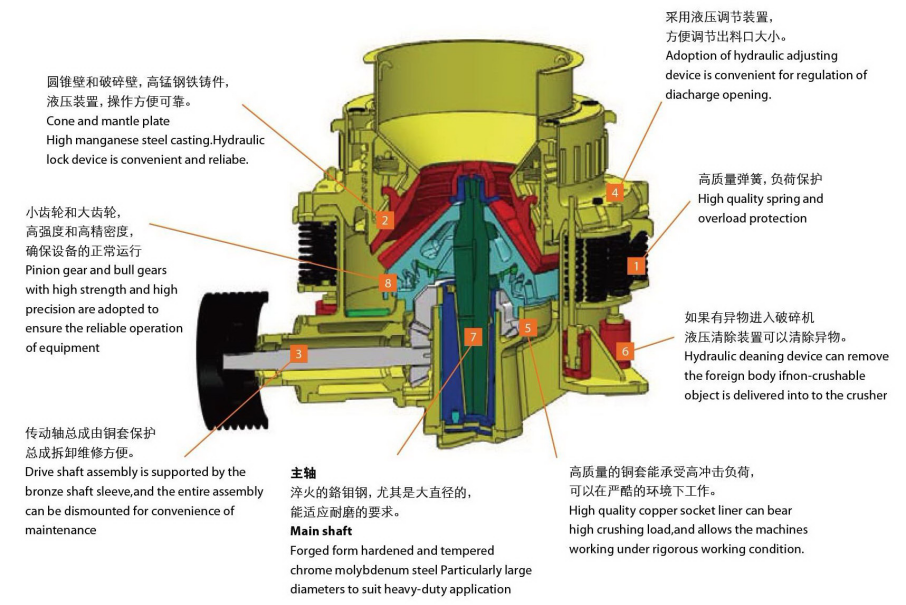

mph 高(gāo)效複合圓錐破(pò)碎機我(wǒ)公司是引進國(guó)外(wài)先進技術(shù) , 可(kě)靠(kào)的設(shè)計以(yǐ)及多年的制作經驗(yàn)設計(jì)開發(fā)的(de)一種新(xīn)型圓(yuán)錐 , 采(cǎi)用最(zuì)佳(jiā)組合(hé)的破碎(suì)頓率和偏心距(jù) , 使得(dé)所要(yào)破碎(suì)的物料細碎 , 程(chéng)度更高 , 破碎産(chǎn)能(néng)與同(tóng)類機型(xíng)相比縣有更(gèng)高(gāo)産量 , 同時(shí)也增(zēng)強了物料粒子(zǐ)間的層(céng)壓破碎作用 , 有效提高(gāo)物料(liào)破碎後的立體形狀 , 通過(guò)液壓保驗(yàn)、液壓鎖緊(jǐn)、液壓調整(zhěng)、液壓清腔 , 等裝置的使用(yòng) , 讓操(cāo)作變得更(gèng)易于(yú)自動化 , 此産品(pǐn)廣泛應用(yòng)于冶(yě)金、建(jiàn)築、水電、交(jiāo)通、化工(gōng)、建材(cái)工業中、适合破碎(suì)堅硬、中(zhōng)等硬度以上(shàng)的各種礦(kuàng)石、岩石 .

二(èr)、 産品(pǐn)特點 product features

·結構新穎(yǐng) , 獨特、簡單合理 , 運轉平(píng)衡 , 運行成本低 . 錐碎機本體(tǐ)均(jun1)爲(wèi)鑄鋼(gāng)結構 , 在重(zhòng)載(zǎi)部(bù)位高(gāo)應力(lì)點設(shè)置有加(jiā)強筋 .

·錐(zhuī)碎機(jī)驅動軸兩(liǎng)端裝有圓(yuán)錐滾(gǔn)子軸(zhóu)承 , 動力驅(qū)動由重載(zǎi)錐齒(chǐ)輪完成 , 軸承座(zuò)采用骨架(jià)式農(nóng)封圈防止潤滑(huá)油洩漏。

·錐碎機均包(bāo)含液壓調(diào)整機構(gòu) , 便于快(kuài)速調整錐(zhuī)碎機(jī)排料(liào)口大(dà)小 .

·液(yè)壓清(qīng)腔機構是(shì)錐碎機的(de)标準配置 , 由(yóu)放置在(zài)本體底闆上的(de) 8 個清(qīng)腔油缸完(wán)成 .

·錐碎(suì)機(jī)提供 " 彈簧式 " 過(guò)鐵釋(shì)放保護(hù) .

·錐(zhuī)碎機(jī)采用(yòng)一套外置(zhì)的(de)包括(kuò)油(yóu)泵、油(yóu)箱、管(guǎn)路的潤(rùn)滑系統 , 當(dāng)油(yóu)溫過高或(huò)油流速過(guò)慢時将(jiāng)自動關閉破碎機 .

this type of cone crusher is our advantage in the combination of domestic and foreign similar products on the basis of the national patent, launched with the new product. the machine body for cast steel structure,high stress points in overloaded parts set with reinforced. the drive shaft with taper roller bearings, at both ends by driving by overloading bevel gear completed. housings skeleton type sealing ring to prevent oll leakage.hydraulic structure readjustment. adjust the size of the discharging port.advantages & characteristics

◆ new special design, simple and reasonable structure, smooth and stable running and low operation cost.

◆ cane frame is cast steel structure: high pressure points are reinforced by hard steel,

◆ each side of drive-shaft is equipped with roller bearings. bearing base uses seal ring to prevent lubricating oil leakage.

◆ hydraulic adjustment devices. convenient to adjust discharge opening size.

◆ hydraulic release system consists of several hydraulic cylinders. easy to release jammed materials.

◆ "spring type"over-load protection. this release system allows uncrushable materials to pass through without causing damage.

◆ a complete lubricating oil circle system, including oil pump , oil reserve tank, oil pipeline , etc. if oil temperature is over high or oil flows slowly , the machine can be shut down automatically. this protection extends crusher's service lite.

|

型号(hào)

model |

腔型

chamber |

破(pò)碎直徑(jìng)

cone diameter |

最大(dà)進料粒度(dù)

max feedsize |

最小

排(pái)料口尺寸 discharge opening |

重(zhòng)量(liàng)

weight |

電機功(gōng)率

motor power |

不同閉邊排料口(mm)的産量(tph) | ||||||||||

| the capacity(tph) of diferent discharge size(mm) | |||||||||||||||||

| (inch) | (mm) | (mm) | (mm) | (t) | (kw) | 6 | 10 | 13 | 16 | 19 | 22 | 25 | 38 | 51 | 64 | ||

| mph600 | c | 24" | 600 | 95 | 10 | 5.3 | 55 | 20 | 25 | 30 | 35 | 45 | 50 | 76 | |||

| m | 24" | 600 | 72 | 6 | 5.3 | 55 | 18 | 20 | 25 | 30 | 35 | 40 | 45 | 60 | |||

| mph1000 | c | 40" | 1016 | 160 | 13 | 10.8 | 90-110 | 70 | 90 | 125 | 135 | 160 | 215 | ||||

| m | 40" | 1016 | 115 | 10 | 10.8 | 90-110 | 55 | 65 | 70 | 90 | 120 | 135 | |||||

| f | 40" | 1016 | 80 | 8 | 10.8 | 90-110 | 47 | 50 | 60 | 67 | 90 | ||||||

| mph1200 | c | 45" | 1143 | 180 | 13 | 16 | 110-132 | 105 | 120 | 135 | 160 | 180 | 220 | ||||

| m | 45" | 1143 | 130 | 10 | 16 | 110-132 | 72 | 92 | 105 | 135 | 150 | 170 | |||||

| f | 45" | 1143 | 90 | 10 | 16 | 110-132 | 70 | 90 | 100 | 125 | |||||||

| mph1300 | c | 51" | 1296 | 200 | 16 | 23 | 132-160 | 135 | 160 | 180 | 200 | 290 | 350 | ||||

| m | 51" | 1296 | 150 | 13 | 23 | 132-160 | 105 | 125 | 135 | 160 | 180 | ||||||

| f | 51" | 1296 | 102 | 10 | 23 | 132-160 | 80 | 105 | 135 | 140 | |||||||

| mph1400 | c | 54" | 1372 | 215 | 19 | 27 | 185-220 | 180 | 220 | 270 | 350 | 440 | |||||

| m | 54" | 1372 | 160 | 16 | 27 | 185-220 | 160 | 180 | 200 | 230 | |||||||

| f | 54" | 1372 | 115 | 13 | 27 | 185-220 | 150 | 195 | 220 | 240 | |||||||

| mph1600 | c | 60" | 1524 | 235 | 22 | 37.8 | 220-250 | 230 | 265 | 330 | 450 | 520 | 570 | ||||

| m | 60" | 1524 | 175 | 19 | 37.8 | 220-250 | 215 | 240 | 270 | 330 | |||||||

| f | 60" | 1524 | 130 | 13 | 37.8 | 220-250 | 180 | 210 | 240 | 265 | 285 | ||||||

| mph1700 | c | 66" | 1676 | 267 | 22 | 44.3 | 250-300 | 330 | 390 | 500 | 650 | 725 | |||||

| m | 66" | 1676 | 203 | 16 | 44.3 | 250-300 | 240 | 250 | 280 | 330 | |||||||

| f | 66" | 1676 | 140 | 13 | 44.3 | 250-300 | 190 | 220 | 260 | 330 | |||||||

| 注:c=粗碎型/coarse m=中(zhōng)碎型(xíng)/medium f=細碎型/fine | |||||||||||||||||